Analysis of Distributed Electric Drive System

With the development of the automobile industry and the increasing awareness of environmental protection, electric vehicles have gradually become the development direction of future automobiles. In electric vehicles, the motor is an important component, which is responsible for converting electrical energy into mechanical energy and driving the vehicle. The distributed drive system is a new type of motor drive in electric vehicles. It has the advantages of short transmission chain, compact structure, and improved tire adhesion distribution and drive efficiency. It can greatly improve the overall performance and energy utilization of electric vehicles.

01 Fundamentals of Distributed Drive Systems

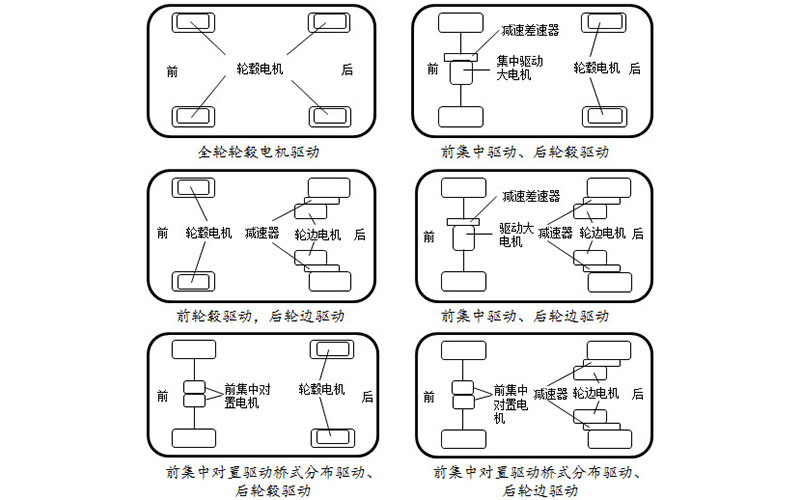

In the distributed drive system, two or more motors drive the respective wheels, and the motors drive the wheels by controlling the torque and speed. Compared with the traditional center-mounted drive system, the distributed drive system cancels the torque transmission of the center differential, so that the motor directly drives the wheels, and the transmission chain is simpler and more compact.

In addition, the distributed drive system can also individually adjust the magnitude and direction of the drive torque through the motor to achieve refined tire adhesion distribution and improve vehicle handling and driving stability. The distributed drive system can also match the optimal efficiency range of the motor with the working conditions of the vehicle, improving drive efficiency and energy utilization.

02 Structure of a distributed drive system

The distributed drive system is composed of two or more motors, steering devices, braking systems, control systems, etc., which independently drive their respective wheels and cancel the torque transmission of the intermediate differential. An electric vehicle drive method. Each motor is installed at each wheel hub of the vehicle, and the torque and speed of the motor are controlled by the motor controller, thereby driving the wheels to move. The steering device is used to control the steering of the vehicle, and the braking system is used to control the braking of the vehicle.

In addition, the distributed drive system also needs to be equipped with a corresponding control system for controlling the torque and speed of each motor and optimizing the distribution of tire adhesion. The control system can adopt centralized control or decentralized control, and can also adopt a mixed control method.

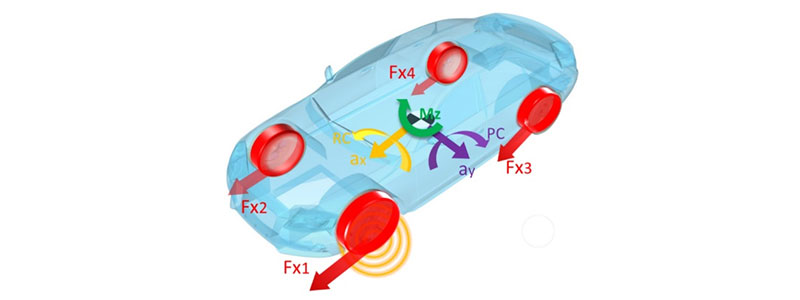

Figure 1 - Schematic diagram of distributed drive vehicle driving

Figure 2 - Chassis drive configuration of a typical distributed drive electric vehicle

03 Performance of Distributed Drive Systems

Compared with the traditional mid-mounted drive system, the distributed drive system has the following advantages:

1. Short transmission chain: In the distributed drive system, each motor only needs to drive one wheel, the length of the vehicle transmission chain is shortened, the transmission loss is reduced, and the efficiency is improved.

2. Compact structure: The distributed drive system does not require a differential, which saves space and makes the vehicle more compact.

3. Improve the distribution of tire adhesion: the distributed drive system can individually adjust the magnitude and direction of the driving torque through the motor, optimize the distribution of tire adhesion, and improve vehicle handling and driving stability.

4. Improve driving efficiency: The distributed driving system can match the optimal efficiency range of the motor with the working conditions of the vehicle, improving driving efficiency and energy utilization.

The distributed drive system also has the advantages of improving the acceleration performance of the vehicle, reducing the power density of the motor, and increasing the flexibility of power distribution.

In short, the distributed drive system is a driving method of electric vehicles with great potential, which is expected to improve the overall performance and energy efficiency of electric vehicles.

However, changes in driving conditions, operating modes, and structural parameters of a distributed drive vehicle will have a huge impact on vehicle dynamics. If there are couplings or overlapping subsystems in the vehicle chassis that lack coordinated control, it will inevitably lead to some complex driving conditions. The overall performance of the vehicle deteriorates and even becomes unstable under working conditions. In order to effectively improve the driving safety, handling stability, ride comfort and driving performance of the distributed drive electric vehicle chassis coupling system, it is necessary to carry out in-depth scientific research on its multi-source excitation coupling mechanism and motion formation mechanism to solve the dynamic performance of the chassis coupling system. Key issues facing collaborative optimization and its domain control design.

The advantage of the distributed drive system is that it can improve the energy utilization rate and overall performance of the vehicle, but in practical applications, it is necessary to solve the problem of efficient matching and collaborative optimization between the chassis configuration design and the vehicle performance. In order to achieve this goal, it is necessary to deeply study the coupling mechanism of the distributed drive electric vehicle chassis and its motion formation mechanism.

One solution is based on model predictive control technology, which can effectively reduce the coupling of the distributed drive electric vehicle chassis system and improve the motion control performance of the vehicle. Specifically, the kinematics and dynamics models of the distributed drive electric vehicle chassis can be established and optimized using optimization algorithms. The optimization algorithm can realize the efficient control of the whole vehicle by adjusting various control parameters.

Another solution is to adopt techniques based on fault diagnosis and fault-tolerant control, which can improve the safety and reliability of distributed drive electric vehicles. In this approach, comprehensive fault diagnosis and fault-tolerant control design of the chassis system are required to ensure the safe operation of distributed drive electric vehicles under various working conditions.

In addition, virtual prototyping technology can also be used to achieve efficient matching and collaborative optimization of distributed drive electric vehicle chassis systems. Virtual prototyping technology can simulate the kinematics and dynamics characteristics of distributed drive electric vehicles, and determine the best control parameters and chassis configuration design scheme through simulation analysis.

To sum up, to solve the problem of efficient matching and collaborative optimization between distributed drive electric vehicle chassis configuration design and vehicle performance requires a variety of technical means, including model-based predictive control, fault diagnosis and fault-tolerant control, virtual prototype and other technologies. In order to improve the motion control performance, safety and reliability of the vehicle.

Figure 3 - Four-wheel distributed drive torque vector distribution principle

04 Conclusion

The distributed drive system is a new type of motor drive, which has the advantages of short transmission chain, compact structure, high energy utilization rate, and fine tire adhesion distribution. It can greatly improve the overall performance and energy utilization of electric vehicles, and is one of the important directions for future vehicle development. In addition, the development of future distributed drive systems requires more efficient and intelligent motor control algorithms and systems to achieve more High energy efficiency and driving experience. With the continuous advancement of technology and the continuous demand of the market, it is believed that distributed drive systems will be more widely used in the future.